Zhuozhou Yesheng Import & Export Co., Ltd.

Products

Contact Us

Add:Shop No.44 of Buidling No .2 Mingliu engiingvangfang, North pinan Street,Hebei Province. China

Tel: +86 15383228955

E-mail:unclejohnson@yesheng-zh.com

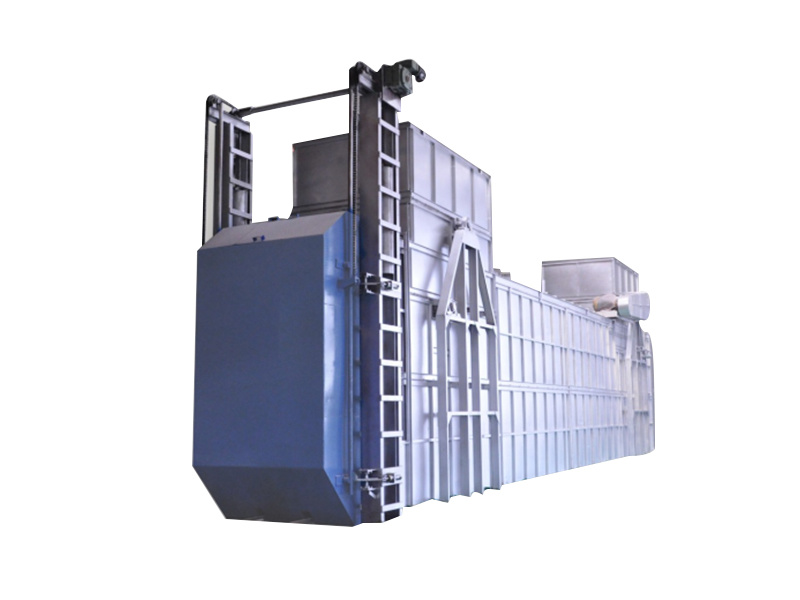

MELTING HOLDING FURNACE ELECTROMAGNETIC STIRRING ALLOY

The heating method is electric radiation or gas; 2. The furnace body is formed by integral casting;

Melting and heat preservation;

Electromagnetic non-contact mixing;

Can support electromagnetic ultrasonic, degassing refining and other functions; 6. The furnace body can be tipped over and moved.

File Download:

Click here!

- Description

-

Product function characteristics

- The heating method is electric radiation or gas; 2. The furnace body is formed by integral casting;

- Melting and heat preservation;

- Electromagnetic non-contact mixing;

- Can support electromagnetic ultrasonic, degassing refining and other functions; 6. The furnace body can be tipped over and moved.

Product application advantage

- Because the electromagnetic stirring accelerates the release of heat and changes the flow mode of melt, the growth of columnar crystals can be effectively inhibited and the grains are refined equiaically. Changing the morphology of precipitated phase reduces macroscopic segregation and microscopic segregation, increases the crystal nucleus, grain and uniform temperature, enhances the effect of solidification in a larger volume and refines the grain at the same time, which is more reasonable to stir in the crystallization process. By electromagnetic stirring, the relative deviation of the chemical composition of the whole furnace melt can be controlled within 10%.

- Can greatly shorten the melting time.

- electromagnetic stirring does not need to open the furnace door, which reduces the heat loss and improves the heating power. The heating time and melting time are shortened, the formation of oxidation slag is reduced, and the furnace efficiency is greatly improved. A large number of application data show that under normal circumstances, electromagnetic halving can shorten the melting time of about 20% of the non-electromagnetic stirring, can reduce the combustion consumption of 10%-15%, can increase the productivity of 15%-30%.

- Due to electromagnetic stirring, the molten liquid can meet the process requirements in a short time, and the stirring is sufficient, which can greatly reduce the metal droplets in the slag layer, shorten the exposure time of the solution to the air, so as to improve the real yield of the metal, and the reduction of slag is roughly 15%-30%. 5. Greatly shorten the uniform time of temperature and composition, and improve the overall uniformity. 6. Suitable for the development and production of a variety of aluminum-based alloys.

Keyword:

Get A Quote

Note: Please leave your contact information, our professional staff will contact you as soon as possible!